Click image to enlarge

Laser cutting services provide the cleanest and most accurate style of cutting. Unlike mechanical cutting devices, a laser will never suffer from dull tooling. Laser cut parts are cleaner and more accurate and have smoother edges than those cut by other processes. And, with advanced CNC software, parts can be rearranged and nested to minimize scrap and maximize the total number of parts that can be produced from a single sheet.

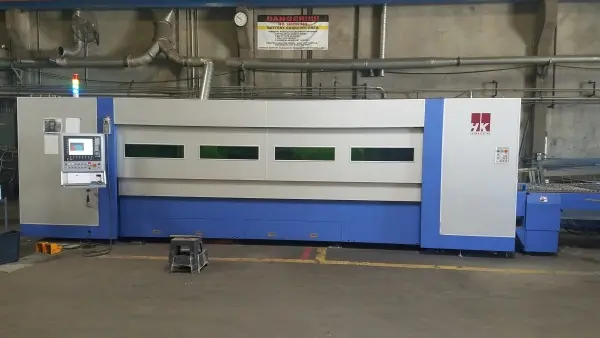

Advanced Laser Cutting Machines

As a part of our newest metal processing service, we offer Fiber Laser cutting. The laser beam is created by a bank of laser lights that are piped through fiber optic cables which are combined and then focus onto the material. Fiber lasers can cut most metals including aluminum, steel, stainless, brass, and even copper and at M&K Metal Co, we have 2 of these machines. The 4000 watt laser has a 5’ x 10’ cutting tables and the 8000 watt fiber laser has a 5' x 12' cutting table. Both lasers have dual shuttle tables which means that material prep times is decreased which ultimately translates into a lower overall cost per part. Call us today at 310-327-9011 to discuss your Laser Cutting project needs today!

Metal Laser Cutting Benefits

Laser cutting is a manufacturing process which can eliminate the need for machining on many engineering jobs, enabling you to save money on manufacturing costs. Some of the more beneficial elements of laser cutting, include:

- Extremely precise

- Cuts complex shapes

- Quick

- Reduced contamination of the workpiece

- Can cut small diameter holes with complex detail

- Requires less energy to operate

- Extremely versatile

Visit or Contact M & K Metal Today to Learn More About Our Laser Cutting Services

We can UPS or USPS small parts and prototypes to you so please send us your drawings or a Request a quote for all your Laser cutting needs. Or, contact us for more information.